Clutches, flywheels or drive shafts for trucks & commercial vehicles

For smooth driving pleasureDrive shafts, clutch discs and the like – the drivetrain is not just a complex system, it consists of many individual parts whose smooth functioning is of crucial importance. In short: a drive is only as strong as its weakest component. As an experienced partner, we can therefore supply you with the best spare parts for all aspects of driveshafts, drive shafts and clutches for trucks, trailers and commercial vehicles.

Thanks to our expertise and years of experience, our spare parts cover the needs of retailers and fleet and vehicle operators alike. Our drives and clutches meet the highest quality standards – at an attractive price.

From, for example, suitable for Iveco and MAN to Mercedes Benz and Renault through to Scania, DAF and Volvo, we stock all common brands. So you don’t have to compromise on your spare parts.

Product categories

Endurance test passed

Our spare parts in the race truckThe largest and most impressive racing series in the world, the Goodyear FIA European Truck Racing Championship (ETRC), is a unique motorsport spectacle in a class of its own.

Since the team was founded in 2016, PE has been supporting the T SPORT Bernau team with high-quality products and custom-made products that pass all endurance tests on the race track.

The incomparable power of modern drive systems

German Engineering for repairs in line with current valueDrives for trucks, commercial vehicles and trailers comprise many different components. The selection of spare parts and accessories is correspondingly extensive. Our experts will be happy to provide you with comprehensive advice. Nevertheless, we would like to take this opportunity to briefly introduce the most important spare parts.

Large range of spare parts and accessories for drives

With our range of spare parts and accessories, we cover all areas of the drive. Your advantage: You really only have to replace what is defective. This saves time and money. Here is a brief overview of the respective components in our store:

- Clutch release fork

- Flywheels

- Clutches

- Clutch cylinder

- Pilot bearing

- Drive shafts

- Rep. kit for propeller shaft mounting

- Clutch release bearing

- Shaft sealing ring

- Inner ring

- Needle bearing

- Bevel gear nut

- Bush

- Sealing ring

Clutch disks

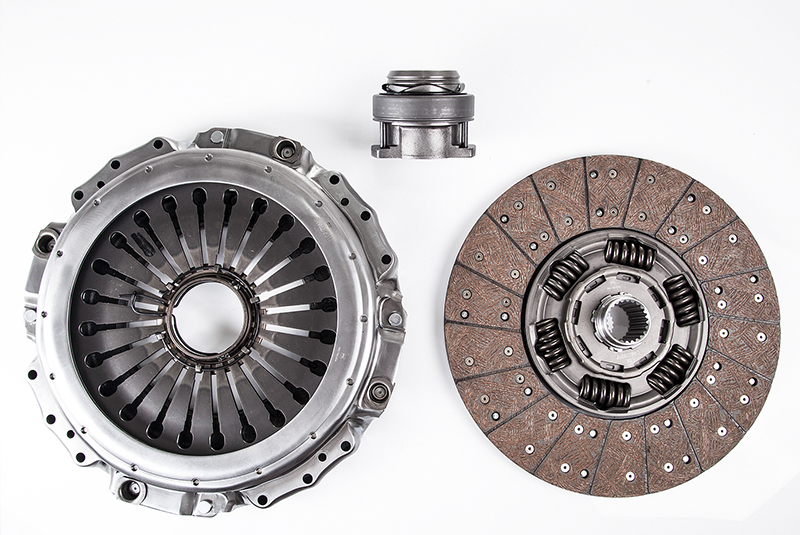

Together with the clutch cover, the clutch disk enables and separates the power flow and ensures overload protection. It also enables smooth starting, fast gear changes, dampens engine torsional vibrations and prevents rattling noises in the transmission.

The clutch disk is crucial for truck control, as it allows the transmission to be separated from the engine. There are different types of clutch plates, including the pressure plate, the driven plate and the intermediate plate for high torques.

The service life of a clutch disk can vary between 80,000 and 150,000 km, depending on driving style, transport weight and road conditions. Defects usually occur due to abrasion or spring breakage caused by improper use, frequent depressing of the clutch pedal or low brake fluid levels. Improper installation can also lead to problems.

Signs of clutch disc defects include partial malfunction, failure to return to the original position, vibrations, unusual noises and poor acceleration. You can check the degree of wear by testing the pedal travel – the earlier the torque transmission begins, the less worn the clutch disk is. A burning smell requires immediate replacement.

Flywheels

The flywheel transfers the torque from the engine to the transmission and reduces vibrations and noise while driving. In the standardized design of the dry friction clutch, a pressure plate is pressed against the clutch disc and the flywheel using a diaphragm spring or coil springs. The spring force generates the frictional connection via the friction surfaces. The most common defects include tooth problems, cracks and broken threads. Causes of defects are improper maintenance, incomplete depression of the clutch pedal and overloading the vehicle.

Clutch release bearing

The clutch release bearing for trucks is an important component of the transmission that is responsible for separating the clutch disks. There are mechanical and hydraulic types, with the hydraulic ones often being more efficient. Defects can occur due to wear and tear or incorrect installation and cannot normally be repaired. Symptoms of a defect are a long depressed pedal and clear noises. Visual diagnosis is complicated and requires professional support. It is recommended to replace the component every 100,000 to 150,000 kilometers, even if there are no obvious symptoms.

Drive shafts

In commercial vehicles with rigid axles, the drive shafts are installed directly in the axle beam. They transmit the torque from the central gearbox to the wheel hub and the hub gear. A drive shaft enables power to be transmitted from the gearbox to the wheels. It consists of an axle journal and a ball joint on the wheel side, which allow movement in all directions. There is a tripod or constant velocity joint on the side facing the gearbox, which enables a uniform rotary movement and compensates for movements in the vehicle suspension. Drive shafts are designed to be robust and maintenance-free and normally last the life of the car. However, wear or damage to the sleeves will shorten their service life. These defects can cause loud noises, in such cases it is usually necessary to replace the cuffs. In many cases, the damaged drive shaft also needs to be replaced. An examination by an expert provides clarity.